I had decided that I would also improve the look of the machine at this time, the large number of carbon fiber components could not just simply remain black.

I settled for a ‘traditional’ look, in my book motorcycle frames should be black and the Ducati is the first motorcycle I have owned that wasn’t.

For the bodywork I went through a series of design iterations, I wanted red (all Ducati’s should be red) but broken with another colour, I also wanted some carbon fibre to be seen. This resulted in the black and white checker stripe where the black is the carbon fiber of the underlying component, white panels bordered by a carbon fiber line break up the large expanse of red on the tank, side panels and seat cowl. Custom airbrushing was incorporated into the seat cowl and belly pan.

The work was entrusted to Sudden Impact in Dagenham, they were able to grasp the concept and their master painter Clayton set to work, it took many many hours to complete, each checker square had to be individually masked, 20 coats were applied and no difference in depth can be felt between the carbon fiber and colour coats. I was very pleased with the result.

The frame was shorn of superfluous bracketry, tabs for securing the wiring welded on as were brackets for the preload adjuster and Anderson power plug, the tail shortened to accommodates the ‘half chop’ teatra, the large casting flash on the swing arm was removed and the welds blended. The whole lot was dispatched to Aerocoat for powder coating in high gloss black

As the engine was to be completely stripped for modifications, the opportunity was taken to powder coat the engine castings. This involved the removal of all bearings, seals and studs, and the stripping of the existing coating, all casting flash marks were removed. Again the work was entrusted to Aerocoat with the finish in gloss black. Great people they never lost one bit.

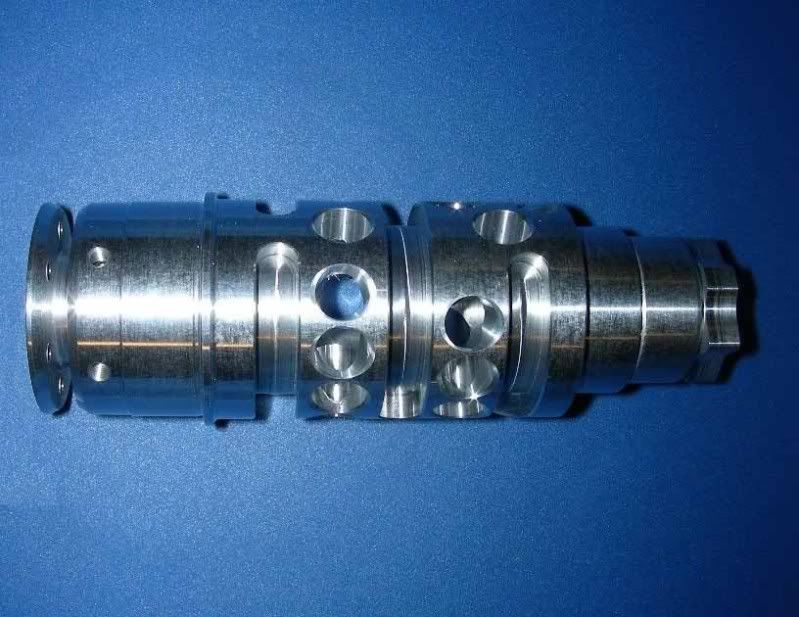

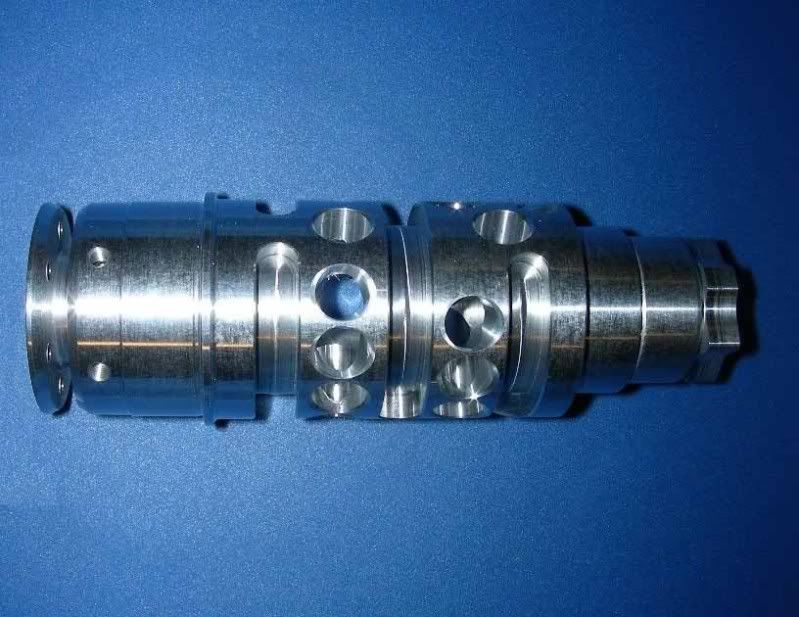

Meanwhile, the engine components were being worked on by JHP, the crank was lightened and balanced, RS Pankle titanium H beam connecting rods were fitted, the heads were machined to accept Pistal RS 13.5:1 pistons. The gears were lightened by Kaema in Germany also very helpful people.

Linear Mode

Linear Mode